The truck stood still outdoors for over 50 years in a field of wrecks… this is a rare vehicle with only 4 identified in Europe, including UNIVEM’s. Two are restored and operational: one in the UK and one in the Netherlands. We undertook this project because the vehicle is complete and unmodified. Furthermore, the majority of degraded parts are plain flat metal sheets, not too difficult to restore.

As soon as the truck arrived, september 18, 2015, work began with the clearing of brambles that grew throughout both the truck and the crane. It was followed by a thorough cleaning and ended with the Kärcher. A rear wheel was blocked because of its brake shoes being caught in rust and dust. It was eventually released. But with one blocked wheel we had no other solution to unload the truck from the low bed trailer than to pull it with our mighty Pacific tractor. Unfortunately this caused the breakdown of an axle shaft that hopefully we have been able to supply since.

10/17/2015: the boom is removed, awaiting sand blasting. Our 1964 Griffet crane truck has been useful again ! (see section “Vehicles of the association” / “Other” / “Griffet”).

10/24/2015: the truck cab has been removed and the truck sheltered in our garage, a radical change for this vehicle after 50 years in the open, exposed to the elements …

Early November : the cab front pannel is cleared of all its fittings while the large crane cab is disassembled for repair.

The cylinder head has been removed from the truck engine. The engine internal parts look good : the control of the cylinders shows moderate wear ranging from 8 to 10 hundredth of millimeter for a bore of 130 millimeter, which is excellent.

No visible scratches in the cylinders, the engine might well be free to rotate but blocked by fittings like the water pump or the compressor.

The gear box cover has been lifted and the gearing is visually in good conditions (some minor rust spots on some teeth, but really nothing to worry about).

11/07/2015: removal of the crane cab

14/11/15: removal of the Fuller gearbox and Hercules HXD engine while work makes great progress on the truck cab.

Being working on sheet metal, Pascal made us a sign by laser cutting which clearly announces what happens in this place! With backlight, it’s beautiful !

- OLYMPUS DIGITAL CAMERA

- OLYMPUS DIGITAL CAMERA

11/17/2015: the Hercules HXD engine turns by hand ! It is not blocked. The oil pan has been removed and the lower engine looks in very good condition at visual inspection. A brake chamber was removed and tested at 7bar, it works perfectly well. But since we were able to supply new diaphragms they will be changed later on. Spark plugs have been removed on the Quick Way IHC U9 engine and diesel fuel dropped in the cylinders. Everything was disconnected around the engine for its imminent removal from the crane.

11/21/2015: the IHC engine of the Quick Way crane has been removed and sits now on the ground. The weight of this engine was at the tip of a cantilever structure rather unbalanced since the truck cab, engine and gear box were removed.

The crane engine sits now on a pallet ready to be serviced as soon as the truck engine is rebuilt. The 10 wheels of the truck have been taken off. The Hercules HXD engine is now open, it is in good condition. Some pretty worn out rod bearings need replacement. The clutch disc is damaged and needs repair (4 sectors are fractured and detached from the disc). 11 new tires have been purchased and already delivered.

11/28/2015: beginning of removal of hub and drum assemblies.

12/05/2015: sand blasting of the truck cab

12/12/2015: Karcher cleaning of the engine block. The 11 wheels have been delivered to a truck tire shop that will remove and discard the old tires.

12/31/2015: many small tasks performed during Christmas and New Year holidays, the engine block has been painted inside out. The transfer case has been opened. If there is no more an oil level, it is however well oiled and gears look like in good condition.

January 2016: the hand brake is eventually released as are the control levers on the transfer case. The engine pulley has been fully renovated and serviced for an additional 70 years ! The steering drag link has been removed to be renovated.

The strut for a bearing of the front winch power shaft was broken. Though made of cast iron, we have been able to weld together the two parts. The damaged truck front bumper has been removed and fixed with a 20-ton press. The trestle on which the crane boom rests when the truck is on the road has also been removed, awaiting sand blasting. The smaller winch drum has been unlocked. The two parts making the crane boom have been separated, awaiting sand blasting. By so doing, the beautiful manufacturer’s plates “Quick Way Truck Shovel” were made loose and set aside for restauration.

Model maker “Gaso-Line” issued a 1/48th resin scale model to build of the Brockway C666 with its Quick Way crane. We feel supported in our efforts! On our side, UNIVEM issued a coffee mug bearing the image of a C666. Contact us to get yours!

February 2016: the crane, or what was left of it following previous disassemblies, has been removed from the truck and directed to the Kärcher station. It gives a better access to the rear part of the truck chassis.

March 2016: assembly of the truck dashboard, further processing of the chassis front to rear (cleaning, phosphate treatment, anti-rust paint), renovation of the water pump, disassembly and opening of all the brake chambers, disassembly of the compressor, plasma torch cutting of the sheet metal plates for the crane floor, unlocking of the clutches and brakes of the crane which made possible to set in motion all the gears for the first time in 50 years!

The mark of the steel maker “Bethlehem” was found on the truck chassis.

The truck radiator has been tested with water: big leak that will need to be fixed.

The crane IHC U9 motor manifolds have been removed : bad surprise, the channels are full of rust flakes. For the time being though, we concentrate on the truck and its motor, this problem will be addressed later on. We already know that parts for this motor are extremely difficult to find.

April 2016: a pause… UNIVEM is mourning, Gérard Leck died, he was very active on the project. Moreover, our efforts have concentrated on making a sand blasting place in a large container and also on preparing for the traditional commemorations of may 8 and june 6. Even so, Pascal is making progress on the crane body work. Sheet metal has been purchased and bent to shape to be welded to form the lower belt of the crane cab which was badly corroded.

The truck engine parts (block, cranckshaft, pistons…) have been brought to a professional for an overall check.

May-June 2016: the truck front winch is removed and entirely taken apart for renovation. All winch cable roller guides now spin freely. The steering wheel has been removed (with difficulty, so much corrosion) and the new one installed temporarily. Eventually, the chassis number is found on the right side whereas the TM indicated it on the left side : 12426. A forged hook has been saved for the Quick Way crane which is missing it. The relay valve of the brakes has been partially opened : the inside is neat and clean, the rubber membrane looks very good. Some gaps between the chassis and its reinforcement plates have been cleaned with a jig-saw and treated appropriately. The 4 small drums used to wind and stretch the cables that block the rear axles when the crane is operating havec been freed. Small victory but a lot of hard work to get there !

The rear part of the chassis has been cleaned with a pneumatic needle-gun, then treated with an anti-rust product. It is now painted orange. Wheel drums have been given to a professional for rectification. The heater plate of the admission manifold has been manufactured : the original one in cast iron was broken in several pieces. Work continues on the engine, more extensive that first thought. The gearbox has been opened to reveal an excellent internal condition. The half-rear bumper that had been damaged when the truck had been loaded has been fixed with a 30 tons press.

Milestone! The truck frame is now painted “olive drab”, a real turn in the project.

The wheel hubs have been painted olive drab. Wheel hub bearings are being cleaned.

The cylinders head on the International U9 crane engine has been removed. Though not in very good shape the upper engine appears like it can be fixed. Lower engine (crankshaft) still to be investigated.

October – november 2016: the brush guard and the crane boom support have been treated. Winch parts have been treated and painted. The new sterring drag link has been connected to the steering arms. The front winch, completely restored, has been assembled and installed. November 22 : the motor comes back from the professional renovation (bearings, crankshaft, piston rings, valves).

December 2016: cleaning of all the wheels hubs bearings. Disassembly of all rear brake shoes to replace the return springs. Attempt to rotate the IHC U9 engine by heating the most damaged cylinder (a mix of oil and gasoline was burnt inside), but to no avail. Fuel filter is being investigated.

The project now enters a less spectacular phase : after having taken apart large components, now is the time for small parts renovation. Very time consuming and not very impressive photos like at the beginning. But work continues on a regular basis !

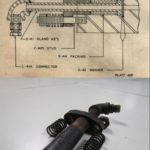

Beginning of 2017, renovation of rear axles brakes : brakes shoes springs, brake chambers membranes and springs. All springs have been manufactured by a specialized company according to the original models. Renovation of the truck cab floor which was very much damaged by 50+ years of rain and snow is almost done.

2017: the rear brake system is being made anew with replacement of the brake chambers membrane and springs (refabricated according to the models). The cab floor, very much damaged, is also being made anew. April: the front and rear brakes are renovated with all the air piping. The rest of the air brake system and piping will be done when the motor is installed. May: the cable system that stabilizes the truck during crane operation has been renovated, new cables have been installed around both rear axles. In May, the crane winches as well as the rotation clutches have been removed to be cleaned and to give a better access to the crane structure that will be soon sand blasted. The crane boom has been sand blasted and treated. A lot of repair work is being done on the left fender of the truck that was pretty damaged by 50+ years of rain and snow : it is now ready to be put on the truck when the motor is ready..

Work on the truck motor resumes after it came back form crankshaft rectification. The Perkins diesel engine that we found for the crane has been cleand with the Karcher. A problem bugs us for the time being : the crane does not rotate on its base. The 4 big rollers have been removed. We tried so far different methods, none worked (heating, pulling, lift-jack between the two parts…). But no doubt, we will succeed !

- DCIM100MEDIADJI_0032.JPG

August 11, 2017: the Perkins crane engine that we recovered “in the forest” has been started following oïl change: https://youtu.be/NnH7ZubgHNY

August 15, 2017: the chassis is on its wheels

September 2017: crane structure is sand blasted and coated. We had a problem from the very beginning: the crane would not rotate on its base. So we had to take apart everything. We started by removing the four big rollers but that didn’t help. Eventually we had to remove the very big nut that holds the crane on its base. And to achieve that, we had to make a special big wrench ourselves. In the end, it turns out that the different parts are not damaged. It was just some old dry grease and bits of rust that jammed everything. But it took us a whole day just to extract the shaft.

Autumn 2017: The heavy base of the crane was completely cleaned and primed.

The lubrication holes on the crane main rotation axle were cleaned (the task was extremely complex, as the grease was very old and therefore very hard. It was trapped in curved channels. We managed to get rid of it, patiently cleaning it with a diluent, and a small spring mounted at the end of a drill!).

January 2018: The crane was left outdoor for more than 50 years. Therefore, a slight corrosion problem appeared under each of the four big rollers. Pascal did a wonderful job by welding the defects. Every small piece of the winch clutch and crane rotation clutch were cleaned. The reassembling is pending.

On the Perkins engine found in the forest for the crane, the water pump (which can’t rotate anymore) and the radiator were dismantled to be overhauled.

- recharge chemin de roulement galets grue 25-01-2018

- recharge chemin de roulement galets grue 25-01-2018

- radiateur et pompe à eau Perkins

- radiateur et pompe à eau Perkins

- radiateur et pompe à eau Perkins

- Moteur Brockway 13-03-2018

- On retourne le moteur du Brockway 13-03-2018

- Moteur retourné 2018-03

- Démontage vanne de frein 13-03-2018

- Freins Brockway 17-03-2018

- dav

- dav

- dav

Summer 2018: the reassembling of the crane and the engine begins!

- ??????????????????????????????????????????????

- ??????????????????????????????????????????????

- Août 2018 – Remontage de la grue

- Août 2018 – Remontage de la grue

- Septembre 2018 – Remontage de la grue

- Septembre 2018 – Remontage du moteur

- Septembre 2018 – Remontage du moteur

- Septembre 2018 – Remontage du moteur

- Septembre 2018 – Remontage du moteur

- Septembre 2018 – Peinture du moteur

- Septembre 2018 – Peinture du moteur

- Septembre 2018 – Peinture du moteur

- Septembre 2018 – Peinture du moteur

- Septembre 2018 – Plancher de la grue

- Septembre 2018 – Plancher de la grue

- Septembre 2018

- Septembre 2018

- Septembre 2018 – Un des treuils

- Septembre 2018 – Un des treuils

- Octobre 2018 – Plancher de la grue

- dav

- sdr

October 2018: The floor of the crane is completed. At the end of the month, the engine is started for the first time since the begining of the restoration! You can see the video here.

- Premier démarrage du moteur !

- Décembre 2018 – Rodage du moteur

- dav

December 2018: First elements of the crane winch are put back together. The braking circuit is re-assembled. The gearbox is coupled to the engine.

- Décembre 2018 – Remise en place d’un des treuils de la grue

- Décembre 2018 – Remise en place d’un des treuils de la grue

- Décembre 2018 – Remise en place d’un des treuils de la grue

- Décembre 2019 – Mise en place du sytème de freinage

- Décembre 2019 – Mise en place du sytème de freinage

- Décembre 2019 – Mise en place du sytème de freinage

- Décembre 2018 – Rechargement d’un des treuils

- Décembre 2018 – Rechargement d’un des treuils

- Décembre 2018 – Mise en place delaboîte de vitesse sur le moteur

- Décembre 2018 – Mise en place delaboîte de vitesse sur le moteur

- Décembre 2018 – Mise en place delaboîte de vitesse sur le moteur

January 2019: The cab and the crane boom are painted! The engine and the cab are re-assembled on the truck! Electricty is done just after and for the whole month of February.

- Janvier 2019 – Mise en peinture de la flèche de la grue

- Janvier 2019 – Mise en peinture de la flèche de la grue

- Janvier 2019 – Mise en peinture de la cabine

- Janvier 2019 – Mise en peinture de la cabine

- Janvier 2019 – Mise en peinture de la cabine

- Janvier 2019 – Remise en place du moteur

- Janvier 2019 – Remise en place du moteur

- Janvier 2019 – Remise en place du moteur

- Janvier 2019 – Remise en place du moteur

- Janvier 2019 – Remise en place du moteur

- Janvier 2019 – Remise en place du moteur

- Janvier 2019 – Remise en place du moteur

- Janvier 2019 – Remise en place du moteur

- Janvier 2019 – Remise en place du moteur

- Janvier 2019 – Remise en place du moteur

- Janvier 2019 – Remise en place du moteur

- Janvier 2019 – Remise en place du moteur

- Janvier 2019 – Remise en place du moteur

- Janvier 2019 – Remise en place du moteur

- Janvier 2019 – Remise en place de la cabine

- Janvier 2019 – Remise en place de la cabine

- Janvier 2019 – Remise en place de la cabine

- Janvier 2019 – Remise en place de la cabine

- Janvier 2019 – Remise en place de la cabine

- Janvier 2019 – Remise en place de la cabine

- Janvier 2019 – Remise en place de la cabine

- Janvier 2019 – Remise en place de la cabine

- Janvier 2019 – Remise en place de la cabine

- Janvier 2019 – Remise en place de la cabine

- Janvier 2019 – Remise en place de la cabine

- Janvier 2019 – Remise en place de la cabine

- Janvier 2019 – Electricité sur le Brockway

- Janvier 2019 – Electricité sur le Brockway

- Janvier 2019 – Tableau de bord du Brockway

- Janvier 2019 – Tableau de bord du Brockway

- Janvier 2019 – Tableau de bord du Brockway

- Janvier 2019 – Tableau de bord du Brockway

- Mise en place d’un isolant sur la cloison pare-feu

- ??????????????????????????????

March 2019: Brake circuit is overhauled. Details are done: battery tray, cab floor, pedals, exhaust,… Several parts are painted such as fenders and front grille. They are put back together and the truck is now proud-looking!

- Support de siège refait

- Bonbonnes du circuit de frein

- Les batteries dans leur rack

- Mise en place de l’échappement

- Mars 2019 – Mise en peinture des marche-pieds

- ??????????????????????????????????????????

- Mars 2019 – Remise en place de la calandre

- La calandre en place !

September 2019: Crane boom support is reinstalled, as well as the crane boom!

- Septembre 2019 – Mise en place du support de flèche

- Septembre 2019 – Mise en place du support de flèche

- Septembre 2019 – Mise en place de la flèche

- Septembre 2019 – Mise en place de la flèche

- Septembre 2019 – Mise en place de la flèche

- Septembre 2019 – Mise en place de la flèche

- Septembre 2019 – Mise en place de la flèche

- Septembre 2019 – Mise en place de la flèche

- Septembre 2019 – Mise en place de la flèche

- Septembre 2019 – Mise en place de la flèche

- Septembre 2019 – Mise en place de la flèche

September 2020 : With all the different projects launched by Univem, the Brockway’s one was paused again. It begins again now with the crane engine, drums and commands installed!

- Septembre 2020, Remontage treuil et moteur

- Septembre 2020, Remontage treuil et moteur

- Septembre 2020, remontage commandes grue

- Septembre 2020, Remontage treuil et moteur

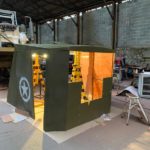

Summer 2021: After another break, the project goes on, with progress on the crane cab panels.

October 2021: crane cab is finally back on the frame!

Stay tuned!